The modern manufacturer has a plethora of advanced technology options to choose from. Industrial and manufacturing firms are investing in digital technologies both due to and despite headwinds in their respective operating environments, such as tariffs, shortages of raw materials or components, regulatory compliance, skills shortages, and competitive pressures. Digital transformation spend across the 10 markets we studied is forecast to grow by a 14.1% Compound Annual Growth Rate (CAGR) and reach US$382 billion in 2030.

In this post, 12 forward-looking manufacturing technologies are highlighted, along with six notable vendors.

Table of Contents

1.) IoT Connections

2.) Simulation Software

3.) Digital Twins

4.) SCADA/HMI Software

5.) Real-Time Location Systems

6.) Augmented Reality

7.) Robotics

8.) Manufacturing Execution Systems

9.) Machine Vision

10.) Private 5G Networks

11.) Smart Manufacturing Platforms

12.) Industrial Artificial Intelligence

Key Takeaways:

- Manufacturing Challenges Lead to Technology Investment. According to ABI Research survey results, 87% of manufacturers plan to make more use of technologies in the coming years. From reshoring projects due to new U.S. tariffs to persistent labor shortages, manufacturing firms are contending with a wide range of challenges that require technology investment.

- Digital Maturity Differs Between Greenfield and Brownfield Production Sites. Another ABI survey indicates that 51% of brownfield manufacturing facilities have not evolved beyond early automation. A not insignificant portion is still fully human-controlled. In contrast, greenfield sites are far more likely to be digitally transformed as of 2025. For example, 84% of German greenfield production facilities have achieved at least Modern Factory Maturity.

- The IoT Is Essential for Improved Visibility. Manufacturers can gain better operational visibility using Internet of Things (IoT) sensors and software systems that provide visibility and actionable insight. Organizations are turning to robotics and other automation technologies to alleviate the impact of widespread labor shortages. However, our survey results indicate that the manufacturing sector is still at an early implementation stage of IoT technologies.

- Increased Demand for Immersive Technologies. Augmented Reality (AR), digital twins, and simulation tools enhance workplace collaboration, provide a means of testing new product designs, facilitate remote assistance, and improve employee training.

- Artificial Intelligence (AI) Advancements Yield Strong Results. AI is a cornerstone of Industry 4.0, with manufacturers leveraging it for quality control and predictive analytics. Agentic AI is still nascent, but industrial technology giants like Siemens, Schneider Electric, and Rockwell Automation have demonstrated promising early results.

- Cyberattacks Are On the Rise. Cybersecurity has emerged as one of the most important technology investment areas, with the CrowdStrike attack serving as a key motivator. The fear of production downtime and significant financial losses has spurred demand for advanced industrial security tools.

- Cloud Computing Platforms Are Highly Praised. Manufacturers widely agree that cloud platforms improve decision-making, remote monitoring, and supply chain collaboration. Moreover, cloud technology is seen as a technology that can enhance the security of digital environments

- Private 5G Networks Are Critical to Digital Transformation. Industry 4.0 technologies require a connectivity backbone. Private 5G offers superior performance, latencies, and security for manufacturers. Private cellular networks are essential for many data-intensive and sensitive applications such as robotics and asset tracking.

- Software-Defined Automation (SDA) is taking center stage. It is now widely viewed as the core industrial automation trend. Leading vendors such as Bosch Rexroth, CODESYS, Phoenix Contact, Schneider Electric, Siemens, and SUPCON are heavily pushing new solutions aligned with SDA. Traditional automation market heavyweights such as ABB, Emerson, Honeywell, and Rockwell Automation are taking slower approaches to the transition due to perceiving a conservative market environment

Manufacturing Technology #1: IoT Connections

Industrial IoT (IIoT) connections include technologies like sensors, trackers, video surveillance, wearables, and other connections that help manufacturers better understand the flow of operations. These connections reveal key data to operators, such as equipment condition, predictive analysis, product location, etc.

IIoT devices are used by manufacturers to gain operational visibility within the digital factory or the supply chain. Our analysts saw many additive manufacturing firms embracing the IIoT at the International Manufacturing Technology Show (IMTS) last year (see the best of IMTS 2024)

So what can this technology do?

IIoT devices can monitor anything from a machine's performance to the environmental data within the back of a truck used to transport temperature-sensitive goods.

For example, a chemical manufacturer could leverage an Internet of Things (IoT)-connected pressure sensor to ensure the optimal flow of gases or fluids in a tank (predictive maintenance). If there’s a buildup, the IoT solution will detect it and notify operators. As a result, it can prevent plant downtime, which costs the world’s largest industrial and manufacturing firms a cumulative US$864 billion per year.

Or, as another example, manufacturers can deploy massive IoT devices to geolocate Returnable Transport Assets (RTAs). These battery-powered IoT trackers can pinpoint the location of pallets, racks, roll cages, kegs, crates, totes, trays, containers, and other logistics assets. This can prevent theft and reduce costs associated with misplaced assets

ABI Research expects manufacturing IoT connections to increase from 259 million connections in 2024 to 935 million connections by 2030. China and the United States dominate this market, accounting for nearly half of global IoT deployments in manufacturing.

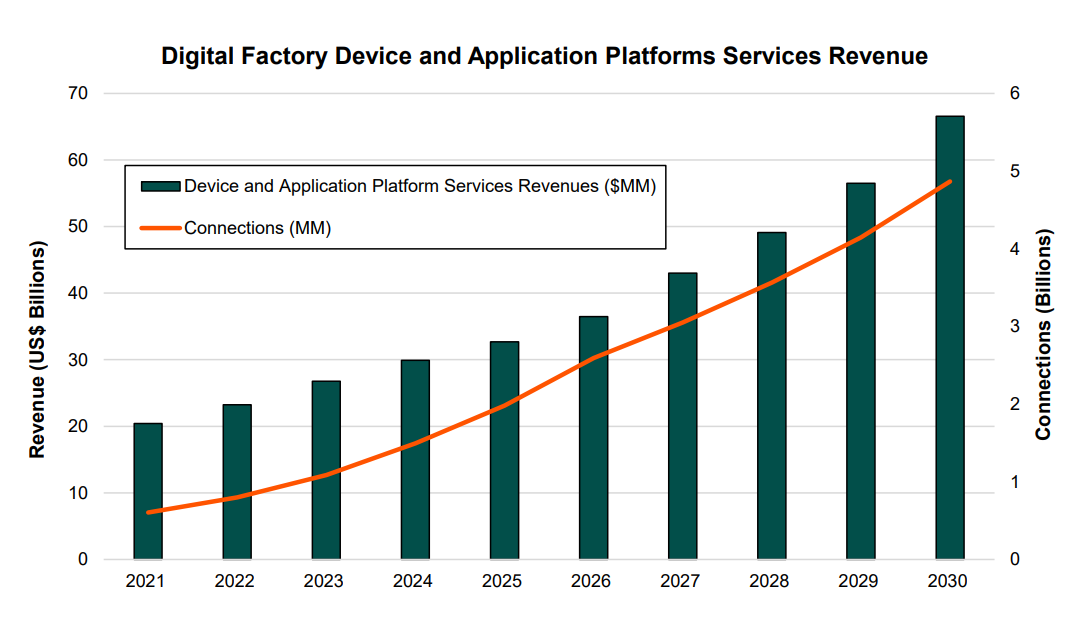

This will translate to manufacturing IoT revenue surging from US$13.2 billion in 2024 to US$44.5 billion by 2030. Our revenue forecasts span physical IoT connections, data analytics services, device/application platform services, network services, professional services, and security services.

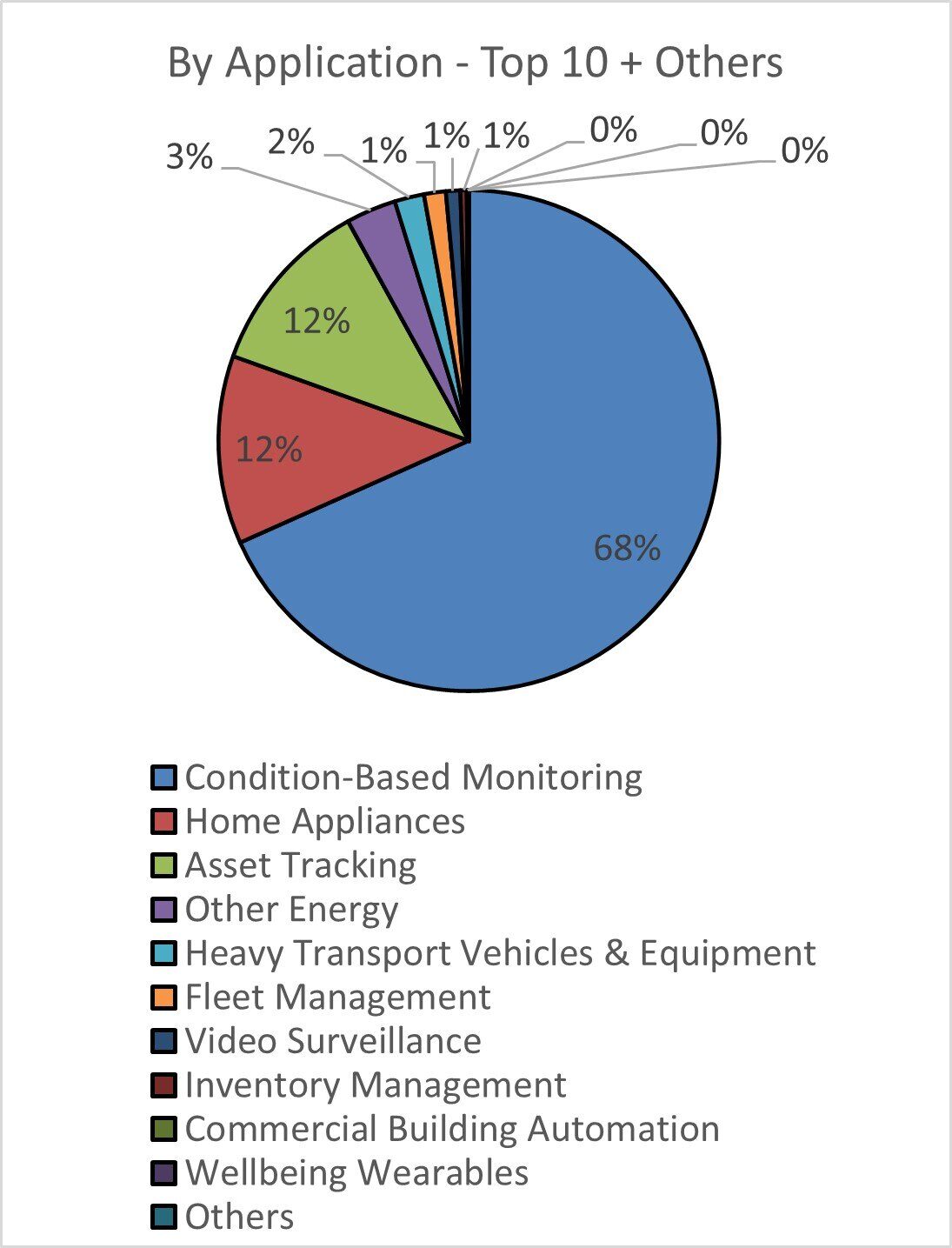

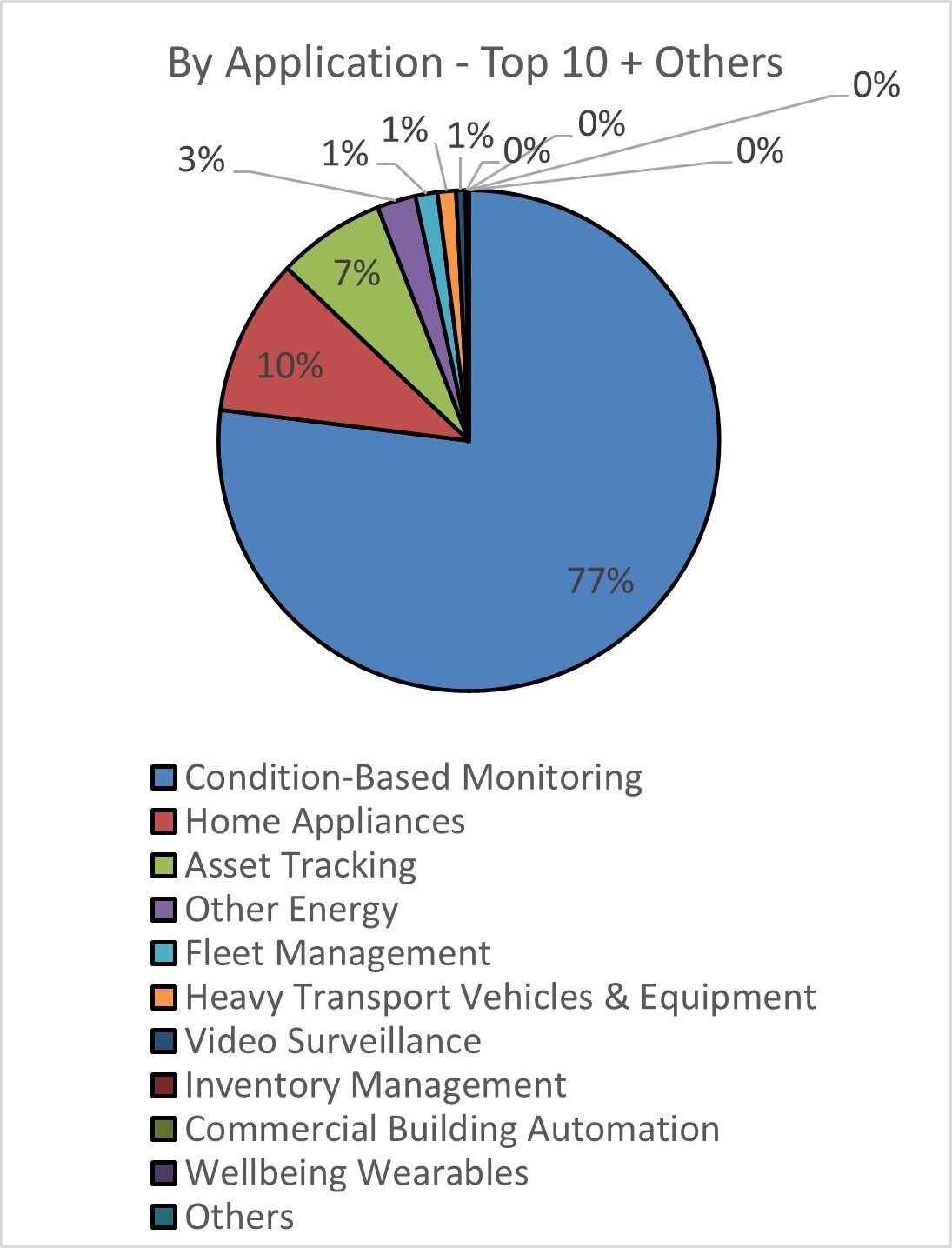

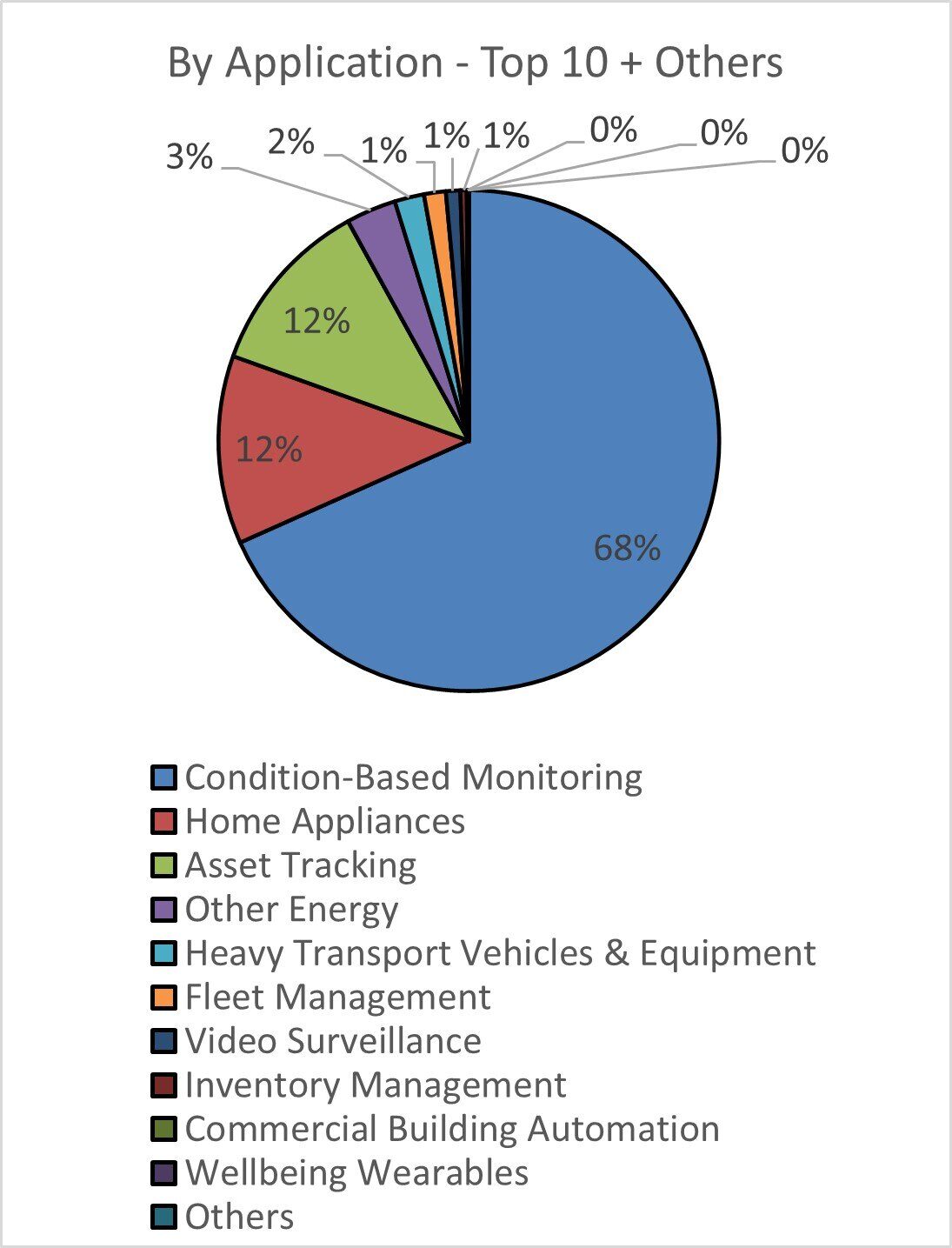

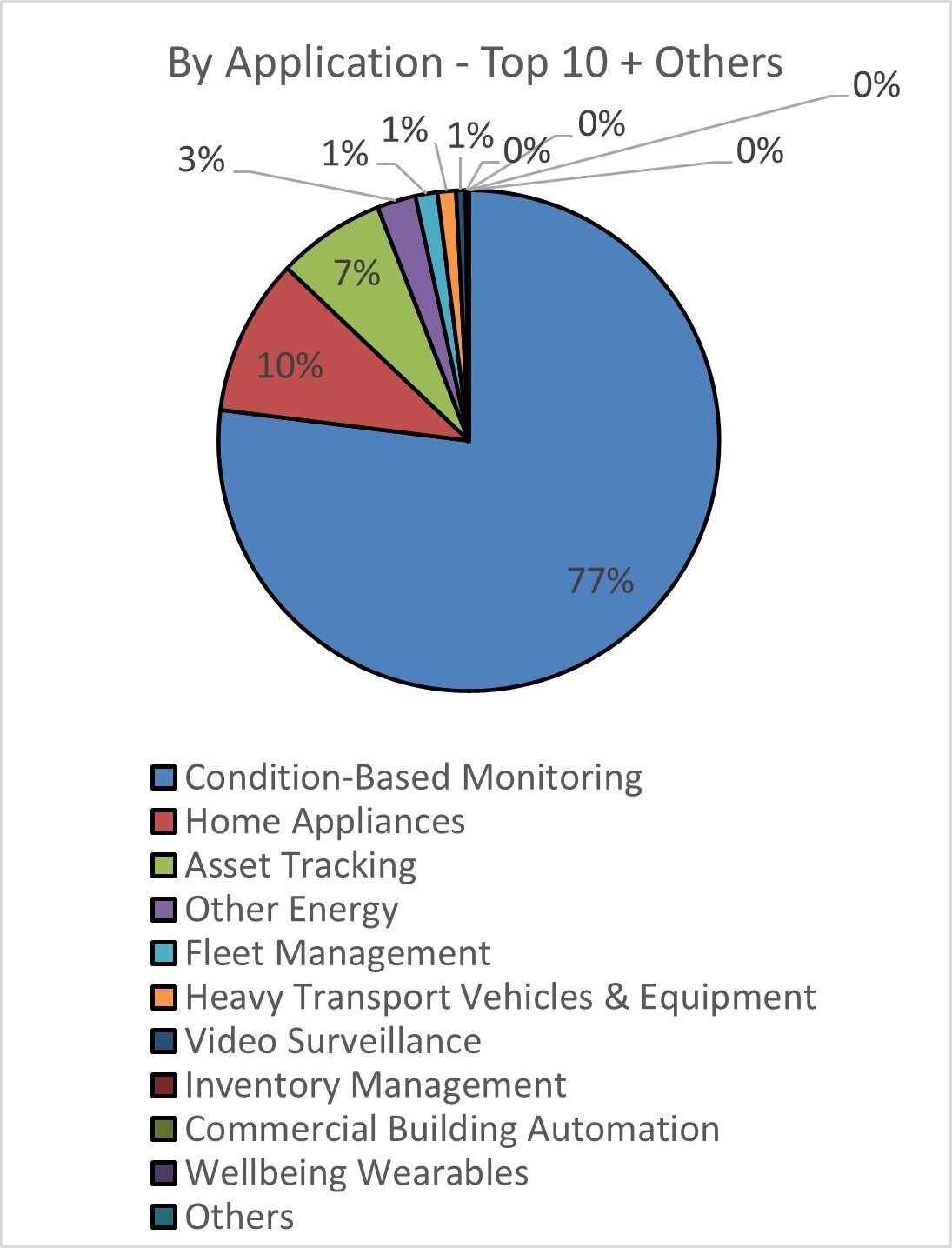

Condition-Based Monitoring (CBM) is the key catalyst for IoT connection and revenue growth throughout the decade, In 2024, manufacturers will spend US$9.05 billion on condition-based monitoring. As seen in the chart below, that accounts for 68% of total IoT revenue among all applications. By 2030, that number will be over US$34 billion in revenue and 77% of total revenue. Data and analytics services are the biggest driver for CBM revenue, followed by device and application platform services.

Chart 1: Manufacturing IoT Revenue by Application in 2024

(Source: ABI Research)

Chart 2: Manufacturing IoT Revenue by Application in 2030

(Source: ABI Research)

Cold chain monitoring is another key application of the IoT. It enables supply chain stakeholders to adjust the temperatures of perishable goods in real time, avoiding product spoilage and increasing business profitability. ABI Research projects the food cold chain market to be worth US$5.5 billion by 2030, indicating a rising demand for reliable IoT solutions.

IoT is also a core aspect of remotely monitoring your assets. IoT remote monitoring platforms enable manufacturers to track the real-time condition of machines, equipment, infrastructure, and other assets. As a result, stakeholders can identify where bottlenecks exist and optimize maintenance schedules.

Manufacturing Technology #2: Simulation Software

Simulation software can be used by manufacturers to see how a product/component or a production line will behave under carefully selected conditions. That way, operators know how to optimize their designs in a way that bolsters productivity and adheres to regulations.

We expect an allocation of US$7.7 billion to simulation software in 2026, with product simulation dominating spending over factory simulation. Growing at a CAGR of 7.2% the market size will nearly double to US$14.7 billion.

The industries spending the most on factory simulation software include computers/electronics, automotive, machinery, and food.

As for vendor breakdown, the technology companies with the largest market shares in the product simulation software market are Ansys (34.4%), Siemens (17.2%), Dassault Systèmes (12.7%), and Mathworks (11.1%). The rest of the market is composed of Altair, Rockwell Automation, Hexagon, Autodesk, Altium, PTC, and Others.

These market shares are depicted in the pie chart below.

Manufacturing Technology #3. Digital Twins

Digital twins are the digital mirror of real-world objects like sensors, devices, machines, processes, systems, people, or even entire facilities. Manufacturers deploy digital twins to drive optimal business outcomes. They provide connectivity, metadata management, data management, increasingly advanced analytics, and often integration with business applications and process systems.

Digital twins can be organized and structured in different ways. This means they come in various hierarchies, topologies, etc. In its most basic form (low fidelity), a digital twin involves:

- Metadata about the respective entity/asset

- A means to monitor it in (near) real time

More advanced (high-fidelity) digital twin technologies contain analytic models (physics-based or increasingly machine/deep learning-based) that enable prediction and simulation. As a result, this allows manufacturers to compare expected versus actual behavior, "what-if" scenarios, and continuous improvement of models through feedback loops. All modern digital twins can interact with an IoT platform or an Application Enablement Platform (AEP).

To understand the benefits of a digital twin, consider the case of Consumer Packaged Goods (CPG) manufacturing giant Mars Inc. The company has leveraged the Azure Digital Twins IoT platform since 2020 at its 160 manufacturing facilities worldwide. Using the Azure digital twin, Mars staff are able to predict outcomes and run production line simulations accurately. Moreover, using digital twins has also benefited Mars in meeting its sustainability goals. The technology helps the firm improve water stewardship at plants and reduce waste and Greenhouse Gas (GHG) emissions.

Manufacturing Technology #4: Supervisory Control and Acquisition Data/Human-Machine Interface Software

Supervisory Control and Data Acquisition (SCADA) systems are the next digital manufacturing technology on the list. Industrial SCADA systems acquire and present data to the Human-Machine Interface (HMI) and central operating terminals. This, in tandem with Programmable Logic Controllers (PLCs), manages industrial equipment, while a historian stores time series, alarm, and event-based data.

SCADA allows operators to see what production is doing in real time, react to alarms, control processes, and change settings locally or from remote central command centers.

A related technology is Human-Machine Interface (HMI) software. HMI software provides and allows manufacturers to design graphical interfaces to monitor and control production processes and assets locally. HMI software can run independently from SCADA, simply as a local visualization and control tool for a single asset or process.

However, due to the symbiotic nature of industrial SCADA and HMI, HMI software is considered a component of SCADA. Indeed, vendors mesh the two tools to differing levels.

As manufacturers continue introducing more IIoT devices to their operations, SCADA and HMI software will be essential.

ABI Research's latest market projections indicate that SCADA/HMI revenue will increase US$13.8 billion in 2025 to US$21.4 billion in 2035. The forecast revenue growth is more aggressive as technology vendors continue to augment solutions with next-generation software-defined capabilities and AI tools, increasing the value of the solutions.

Manufacturing Technology #5: Real-Time Location Systems

The Real-Time Location System (RTLS) is a much-needed technology in the manufacturing industry. The manufacturing sector is losing hundreds of billions of dollars related to the loss of products and equipment. These financial losses are compounded by the subsequent operation downtime induced by the loss of products and equipment.

Using an RTLS, the manufacturing equipment can be tracked and traced, and discovered in real time whenever needed. Pallets at manufacturing sites often move between the site and the customer facilities. Tracking them often relies on physical tags and requires substantial labor and time to trace and manage them. Here again, RTLS technologies provide ample opportunity to automate the tracking of these assets.

This automation becomes even more essential and unavoidable with the ever-increasing size, complexity, and number of assets contained in warehouses.

Manufacturing Technology #6: Augmented Reality

COVID-19 created an immediate need for remote worker enablement, and Augmented Reality (AR) has excelled at remote assistance and expertise for years. ABI Research has tracked the most active use cases for Extended Reality (XR) in the manufacturing sector, and remote expertise has consistently shown the most active users and active implementations in industrial markets.

By 2025, ABI Research estimates more than 8 million monthly active users of remote assistance in the manufacturing industry. Nearly half of those use smart glasses, and the others use mobile devices. XR enables instant access to experts, no matter the location, and reduces wasted time and travel costs. This is a game-changer in making customers happy via remote after-sales services.

Increased efficiency is perhaps the keystone of the XR Return on Investment (ROI) discussion for manufacturers interested in the technology. No matter the AR use case being examined by a manufacturer, efficiency plays a role. Delivering the right content to employees rapidly improves their efficiency. And for even more efficient workflows, industrial companies can add hands-free features, enabled via AR applications, to content access.

A manufacturing assembly line worker, for example, would see an AR-enabled overlay that provides workstation instructions. This way, the employee can continuously work without having to look down at physical instructions or receive support from a human co-worker.

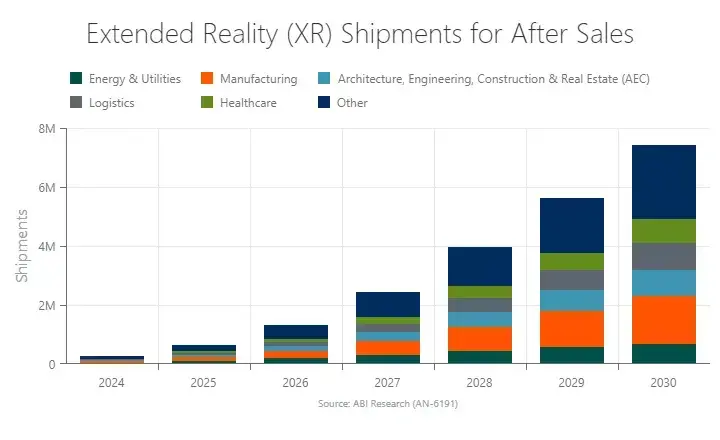

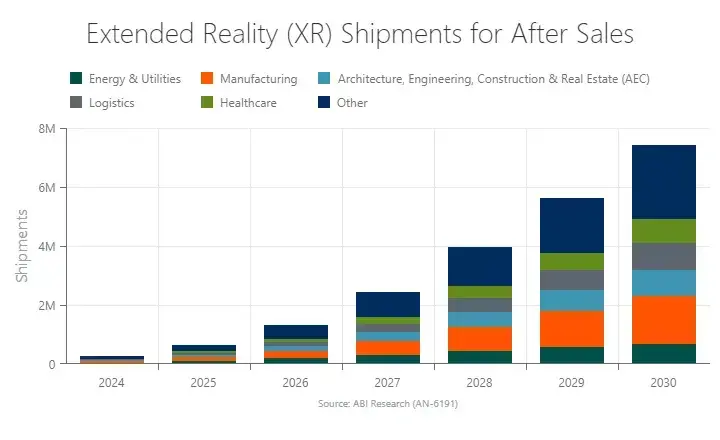

ABI Research forecasts the number of XR shipments for after-sales to grow at a robust 74% CAGR between 2024 and 2030. This brings the total number of annual shipments to 7.4 million in 2030, a far cry from the 269,000 expected in 2024.

XR technologies are also useful for employee training. When using extended reality in the manufacturing sector, employee training is improved due to XR's ability to improve knowledge retention and content efficacy. This makes training more efficient both during and after sessions.

Emerson has given an ROI example for its Plantweb Optics platform in an AR training environment. The example included:

- Five field workers, three new workers hired per year, four months to train, and five subject matter experts available.

- One dispatch per month per field worker, one local expert visit per month, one remote expert visit per month, and 25% less training time.

Results for this relatively small-scale example were US$90,000 in annual savings, with an ROI seen in 6 months with the AR technology.

Manufacturing Technology #7: Robotics

Robotics is an integral aspect of modern manufacturing, especially in the face of labor shortages and increased product demand. ABI Research's Industrial and Manufacturing Survey 2H 2024/1H 2025: Robotics finds that between 40% and 50% of large manufacturers have already deployed robots into operations.

Robots can automate tasks such as materials handling, product picking, assembly, parts unloading, and other critical processes. ABI Research survey results found that 53% of manufacturers adopt robots for quality inspection.

There are four main types of robotics that manufacturers can leverage: industrial robotics, Collaborative Robotics (cobots), mobile robotics, and exoskeletons.

Industrial Robots

The most common forms of industrial robots are as follows:

- Articulated Robots: Classic industrial robots with multiple rotary-jointed “arms.” Articulated robots can range from a simple 2-joint robot to complex 10-joint robots.

- Selective Compliance Articulated Robot Arm (SCARA)Robots: Fast, highly precise six-axis robots typically mounted on a pedestal. Mainly used for handling small objects. Motors are parallel with each other and along a vertical axis.

- Parallel/DeltaRobots: Also called picker robots or spider robots. Most hang overhead, have three or four arms that extend or contract to position the manipulator, and are used for fast, precise movement of objects.

- Linear/Cartesian Robots: Robotic systems used primarily to lift and carry heavy objects linearly over long distances along an x, y, or z axis.

- Other Robot Types: All other classes of robots, such as cylindrical and polar robots.

Collaborative Robots

Collaborative Robots (cobots) are articulated robots designed to interact with human workers in a shared workplace. While the industry has varying definitions for cobots, ABI Research defines a cobot as follows:

- 6 or 7 Degrees of Freedom (DoF) articulated arms

- Force sensing/force control

- No pinch points/sharp edges

- Programming by demonstration

- Lightweight construction/new materials

- Integrated sensors (torque, vision, sonar, etc.)

- Software intelligence

- Compliant/gravity-compensated/back-drivable arms

Mobile Robots

Manufacturers deploy mobile robots to transport goods between production cells or lines in factories and plants. ABI Research Senior Analyst George Chowdhury says the mobile robots market is "driven primarily by material handling and Automated Storage and Retrieval Systems (AS/RS) applications. The growth potential for mobile robots is aided by the fact that many markets are still untapped."

Within the category of mobile robots, there is an important distinction between Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). While AGVs require external infrastructure to move, AMRs, in principle, can navigate an environment without needing external infrastructure.

There are also Remotely Operated Vehicles (ROVs) that are designed to be remotely operated or teleoperated by human operators. Many robots are remotely operated but have a high degree of autonomy and operate at least partially without fiducial markers or magnetic tape. Therefore, these technologies are classed as AMRs. With the increased adoption of AMRs, robotics manufacturers will have a greater reliance on robotics simulation software and the use of Visual SLAM (vSLAM) for perception.

Exoskeletons

Exoskeletons are a relatively nascent robotics technology with immense promise in manufacturing. This wearable solution helps human workers perform industrial applications, such as lifting heavy loads or reaching products otherwise out of reach. Exoskeletons mitigate worker health risks like Work-Related Musculoskeletal Disorders (WMSDs). Moreover, exoskeletons are known to provide manufacturers with productivity gains.

Industrial exoskeletons can either be powered or passive.

- Powered exoskeletons have a power source and will have enhanced capability, but require charging. If the goal is to augment human strength or endurance, there is a greater need for powered exosuits. Though more capable, powered (or active) exoskeletons are considerably more expensive.

- Passive (unpowered) exoskeletons don’t need any power source, batteries, motors, or mechatronics to operate. Unpowered exoskeletons can improve body posture, alleviate pain, and rehabilitate the injured.

Manufacturing Technology #8: Manufacturing Execution Systems

Manufacturing Execution System (MES) software is a primary foundation for manufacturing plants in the Industry 4.0 space. The software tracks, documents, and guides the production process in real time to visualize and control the factory floor. These capabilities are essential to improve production and labor efficiency, support comprehensive digital threads, and enable new business models and best practices in the long run.

As per ABI Research forecasts, the MES market will grow to US$40.3 billion by 2035.

MES software is used to monitor the factory floor, track, document, and guide the production process in real time, and provide further support in optimizing the production process. Each unit is tracked uniquely, end-to-end, from raw material to final product. Holistically, the software supports Overall Equipment Effectiveness (OEE), a composite of availability, quality, and performance. Architecturally, MES software fits between ERP and process control systems. MES solutions cover a broad range of capabilities, so after implementation and customization by manufacturers, it is rare to find multiple MESs that work the same.

ABI Research identifies the following benefits for manufacturers when using MES software:

- Easier product standardization

- Automated and accurate resource management

- Better regulatory compliance

- Machine/system predictive maintenance

- Improved quality management processes

As pointed out in our MES software competitive ranking, the main trends shaping the development of MES software include:

- Low/No-Code Functionality: Democratizes application configuration, reducing deployment time, especially for recipe design.

- Out-of-the-Box (OOTB) Capabilities: Ready-to-use MES functionality with minimal customization, increasingly becoming a standard.

- Manufacturing Ecosystem Integration: MES is evolving to integrate more with other enterprise software, broadening its functionality.

- Cloud-Native/SaaS Architectures: Enables enterprise-wide data access and strategic planning, addressing supply chain fragility.

- AI Integration: AI-supported features, especially in data analytics and generative AI copilots, are gaining popularity in MES solutions.

- Discrete Manufacturing Adoption: Sectors like automotive and aerospace are updating older MES systems to newer, more advanced solutions.

ABI Research's Manufacturing Software Semiannual Update 2H 2025 covers many acquisitions and new partnerships across the MES market. Notable activity includes GE Vernova selling off its Proficy Software to TPG, Tulip acquiring Akooda, and Critical Manufacturing acquiring Convanit. These acquisitions reflect the need to focus on core use cases and accelerate AI integration.

Manufacturing Technology #9: Machine Vision

Machine Vision (MV) is a key enabling technology in automation and human-machine collaboration, especially when deployed at the edge. To date, this Artificial Intelligence (AI)/Machine Learning (ML)-enabled technology has been mainly deployed in quality inspection, defect detection, security, and surveillance.

As more and more manufacturers embark on digital transformation, they begin to collect more data to optimize their internal processes. This has led to the emergence of data-driven Deep Learning (DL)-based MV technology. Many startups have introduced novel applications that are DL-based MV. Conventional MV companies have also started to invest in DL startups to develop in-house solutions to cater to this development.

Related Content

Industrial Machine Vision Systems: Innovations, Key Players, and Differentiators Driving Quality Management Excellence

Manufacturing Technology #10: Private 5G Networks

All the aforementioned manufacturing technologies require a reliable connectivity solution.

Enter 5G.

The top industrial 5G private wireless use cases currently support automation, robotics, and AR. Below are a few examples:

- Quality Assurance: A 5G network can provide manufacturers with lower defect levels by supporting the capture and analysis of items as they are produced. For example, Chinese appliance manufacturer Haier leveraged 5G to significantly simplify its quality assurance process that uses 500-watt industrial cameras to inspect products.

- AR: A private 5G network is essential to support the latency requirements of AR in terms of getting real-time operating information to frontline workers. A remote expert can also support them as if the colleague is there in person.

- Robotics: Coverage offered by 5G networks means that AMRs can receive navigation algorithms, use Light Detection and Ranging (LiDAR) sensors, vision technology, and use mapping for optimal navigation. In addition, AGVs can operate by transporting components and products across the facility. This reduces delivery times and the risk of damage.

- Workplace Safety: Improved safety levels can be expected with a 5G deployment due to the sub-10 Millisecond (ms) reaction time that automatically stops machinery that would injure staff.

- Asset Tracking: 5G, allied with the deployment of sensors throughout the facility or embedded on mobile assets, provides opportunities to constantly track tools, equipment, and employees over a wide area.

Enhanced security is another big investment driver for manufacturers of private 5G. Organizations generate more data than ever and deploy numerous connected devices/systems throughout their facilities. This elevates cyber risk, as there are potential network entry points to leverage and more sensitive data to be stolen.

5G provides highly reliable, low-latency communication, enabling manufacturers to automate and digitize safety-critical and emergency applications more effectively than other wireless technologies. It supports real-time surveillance and monitoring across production lines, while secure remote access solutions can be implemented for Internet of Things (IoT) devices without compromising the manufacturing process. This is particularly important for operations requiring remote oversight.

Additionally, 5G’s low latency allows for automated emergency alerts, ensuring swift dissemination to devices and personnel within facilities, facilitating rapid responses such as evacuations or lockdowns. Furthermore, private 5G networks allow the remote control of safety systems and maintain communication even during power outages, ensuring critical functions like ventilation or emergency shutdowns are activated without delay.

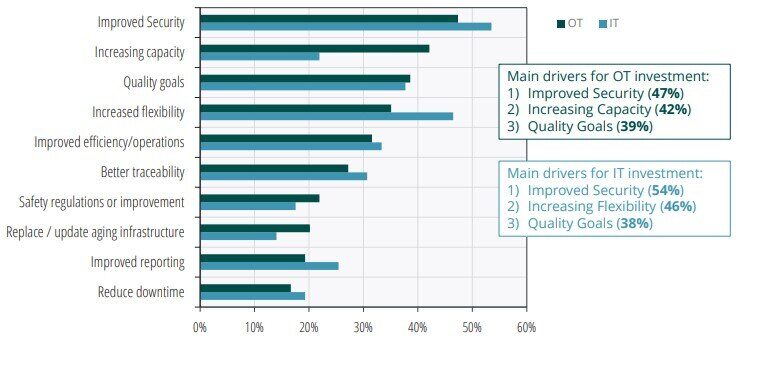

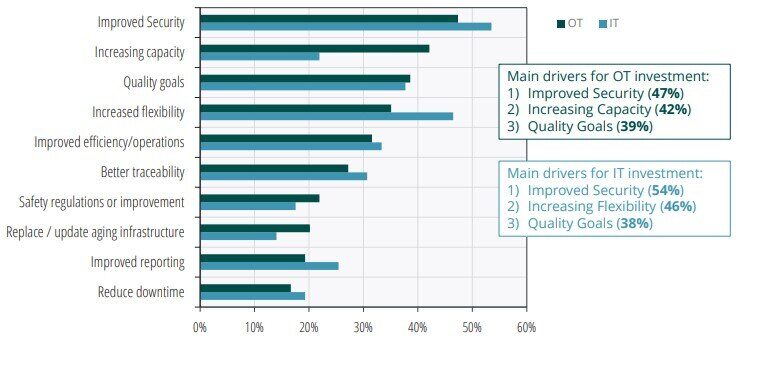

As shared in our recent whitepaper, Private 5G Drivers & Use Cases In Manufacturing, improved security is the top investment driver for 5G in OT and IT settings.

Although enhanced security is a huge focus for private 5G in manufacturing, it's not the only reason for investing in it. 5G also brings the benefits of increased capacity, achieving quality goals, network flexibility, and improved efficiency/operations.

Manufacturing Technology #11: Smart Manufacturing Platforms

Smart manufacturing platforms cover innovations like digital twin support, low-code app development, edge and cloud development, connectivity, and Augmented Reality (AR). Innovators like PTC and Siemens provide advanced platforms for manufacturers to leverage, and ABI Research identifies these two companies as the top innovators in the Smart Manufacturing Platforms Competitive Ranking report.

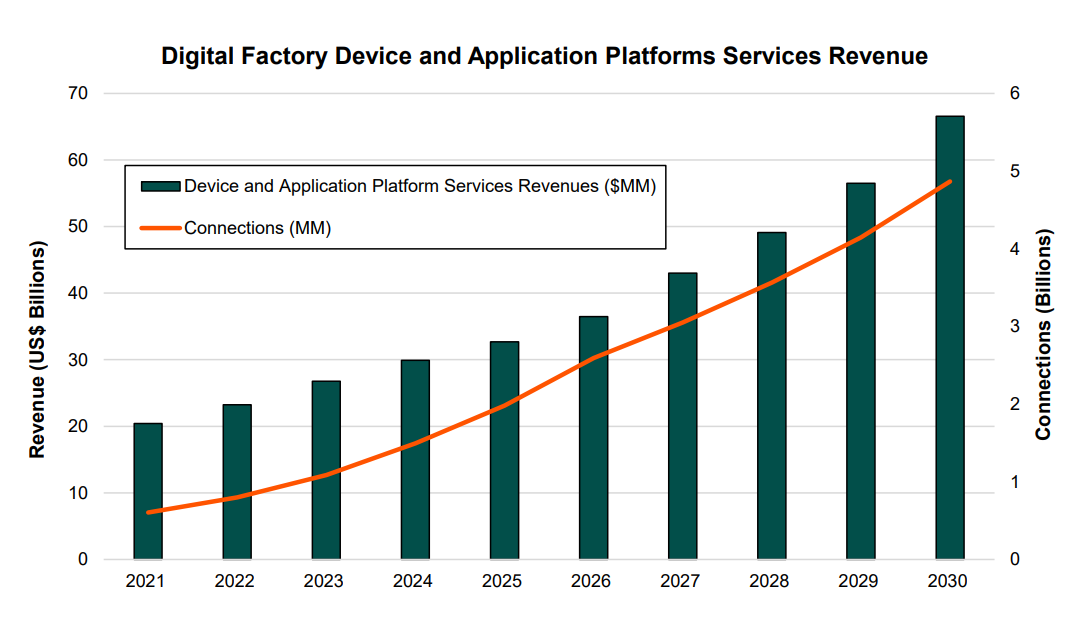

As depicted in the chart below, there will be more than US$66 billion in annual spending on Industrial Internet of Things (IIoT) platforms by 2030, up from roughly US$20 billion in 2021.

Manufacturing Technology #12. Industrial Artificial Intelligence

Artificial Intelligence (AI) innovation is all the hype across industries, with the manufacturing sector being no exception. Nearly all major industrial technology vendors integrate AI capabilities into their products, with Autodesk, HighByte, GE Vernova, Honeywell, Siemens, and others embracing the technology.

AI in manufacturing is evolving fast. ABI Research outlines four main types of AI, each representing a different phase in how machines learn and operate. These types are not just technical categories, but show how businesses can expect AI to improve their workflows, design tools, and factory floor operations.

The four types of industrial AI are:

- Perception AI: This is the most mature and widely adopted form. It allows computers to “see” and “hear” through technologies like computer vision and speech recognition. Machine vision systems used for defect detection are a good example.

- Generative AI: Over the past five years, this type of AI has gained momentum. It can create new content across formats, such as turning text prompts into design models or auto-generating videos. It's commonly used to speed up early-stage product design (see an example from Toyota in Distinguished Analyst Michael Larner's Insight).

- Agentic AI: This current wave of AI goes beyond perception and generation. It can reason, plan, and act independently. Agentic AI automates tasks, syncs data between tools, and improves decision-making in complex environments (learn more in Senior Research Director Ryan Martin's Insight)

- Physical AI: This next frontier focuses on enabling robots and intelligent machines to interact with the physical world with minimal human input. While not yet widely adopted, it’s expected to become a major driver of industrial innovation in the coming decade.

Each type builds on the last, and together, they will shape the future of smart manufacturing.

Tulip’s prebuilt templates for warehouse, quality, and sustainability management speed up deployment and promote industry best practices. The platform is especially strong in pharma and biotech, offering apps that meet strict compliance standards like FDA 21 CFR Part 11.

Tulip includes real-time dashboards, predictive analytics, and robust data tracking features. Manufacturers can build their own analytics tools, improve production quality, and manage inventory and materials in real time. Manufacturers can also leverage Tulip's QMS software if they want a comprehensive quality solution.

Its Assistant feature helps users onboard, troubleshoot, and find documentation across Autodesk tools. This includes guided workflows, configuration help, and real-time support in the eStore.

Furthermore, the vendor supports relational search and cross-platform data insights. Together, these tools help streamline product design, support automation, and improve collaboration across teams.

Windchill includes strong digital twin features, robust compliance tracking, and integrations with supply chain intelligence tools like Makersite. The platform enables advanced AR collaboration through Vuforia and supports configuration-to-order models via CPQ connectors.

PTC stands out for offering free lightweight AR reviews and deep compliance capabilities across industries. Though Gen AI features like part reuse and NLP assistants have been shown, they are not yet widely available.

Join ABI Research's Innovators Network for FREE access to our analysts' latest technology intelligence across the industrial, manufacturing, and supply chain sectors.