2Q 2020 | IN-5848

Registered users can unlock up to five pieces of premium content each month.

Falkonry's Strategy to Operationalize AI for Manufacturing |

NEWS |

Falkonry is an enabling technology company based in Sunnyvale, California that offers Operational Intelligence (OI), Machine Learning (ML), and data science. The company specializes in the industrial and utilities vertical, including chemical, manufacturing, oil and gas, mining, and automotive, with major contract wins with the Joint Warfare Analysis Center (JWA), the United States Air Force (USAF), Boeing, etc. Falkonry offers several products and services, includeing Workbench, Analyzed, and LRS studio. Falkonry Workbench is an interactive cloud-based ML environment with various out-of-the-box solutions, such as predictive maintenance and remote monitoring, as it ingests operational data.

|

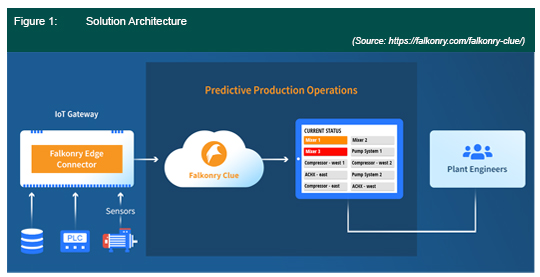

In May 2020, Falkonry announced that it is releasing a new product to the market, with an idea in mind to democratize Artificial Intelligence (AI) for manufacturing companies and penetrate the out-of-the-box solutions market. Falkonry Clue is its new out-of-the-box solution, with plug and play capabilities enabling users to navigate their operational data environment for themselves and have very rapid deployments. The solution is equipped with Falkonry’s proprietary pattern recognition software, enabling users to discover inefficiencies and inconsistencies with real-time operational data. The additional benefit of Clue and Falkonry’s systems is their ability to build predictive models by relying on systems connected in the factory and connected sensors—i.e., Clue does not require large sets of historical data to detect patterns and trends. Finally, this new out-of-the-box solution does not require customization and/or professional services—such market positioning supports the trend for the self-service AI and ML, where full capabilities are packaged as a software kit.

Strategic Positioning and Market Ecosystem Are Critical |

IMPACT |

The real value in Falkonry’s approach is its ability to rethink operational AI, where operational data usage is democratized and available without data scientists, data engineering, or System Integrators (SIs). The company is specializing in pattern recognition and automation of the data preparation executed by integrating ML and AI modeling into a simple software stack or out-of-the-box solution. The deployed method interprets operational patterns in real time and assists Operational Technology (OT) experts to quickly diagnose conditions and malfunctions. ABI Research believes that since Falkonry is not relying on specific hardware, this will help democratize AI and ML adoption and makes Falkonry one of the companies to watch in the industrial IoT sector

However, Falkonry’s visibility is currently limited due to its specific specialization on manufacturing and industrial factory floors, which puts it in direct competition with companies such as Siemens, GE, Seeq, Update, FogHorn, SparkCognition, and others. On the other hand, since Falkonry offers pattern recognition and predictive maintenance in a much more concise and elegant way, GE and Siemens were part of Falkonry’s strategic investors, which allowed the company to grow and create partnerships as a distribution channel via Amazon Web Services (AWS), Azure, TM, SCSK, and others. Such a partnership-competitive investor relationship dynamic also showcases the state and development of the Internet of Things (IoT) ecosystem coopetition.

Manufacturing and Data Analytics Market Set to Boom |

RECOMMENDATIONS |

The industrial and manufacturing verticals are at the forefront of adopting analytics and AI into their IoT systems to ensure optimal performances across various machines, factories, and plants. Diagnostic and predictive analytics helps monitor and maintain assembly lines in a margin-efficient way. The traditional Business Intelligence (BI) tools (descriptive and visualization), as well as spreadsheets, no longer support industrial needs for tracking the production and analyzing the existing inventory and manufacturing assets. Hence, the market is experiencing an uplift in the use of predictive software, prescriptive algorithms, ML, and even operational AI. As a result of significant growth in the analytics market, ABI Research forecasts that revenues for IoT data and analytics services will reach US$37 billion by 2021. Meanwhile, manufacturers and industrial firms will increase their spending on IoT data analytics, which will grow by a 27% Compound Annual Growth Rate (CAGR) over the forecast period, from US$4.92 billion in 2020 to US$19.8 billion in 2026.

Moreover, the adoption of IoT analytics and data management services enables companies to experiment with different parameters like ingredients levels, heating, cooling, and, producing insights and empowering data-driven decision making. The continuous expansion of the IoT-data-enabled ecosystem allows for more precise actions, operation data modeling, and even high-level real-time insights, as discussed in ABI Research’s IoT Analytics and Data Management Services: Strategies of Major Cloud Suppliers (AN-5268) Application Analysis Report.